M4000 High-performance DC Brush Servomotors

High-Performance DC Brush Servo Motors for Industrial and Military Applications

M4000, a 4-inch diameter DC brush servo motor, is a member of Mechatronics' family of high-performance servo motors. The M4000 series utilizes high-energy rare-earth magnets and is designed for tough industrial and military applications. It features a compact size, high power density, and delivers exceptional starting and continuous torque.

The use of rare-earth permanent magnets allows the M4000 servo motors to be significantly smaller than motors with ceramic magnets, offering the same power output. This makes the M4000 an ideal solution for aftermarket field replacements across virtually all motor brands. For new applications, the M4000 offers superior torque-to-inertia and torque-to-weight ratios compared to ceramic or samarium-cobalt-based magnet designs. Low cogging is achieved through skewed laminations, ensuring smooth rotation at near-zero speeds.

Over the past 10 years, a significant number of M4000 servomotors have been successfully installed in various industries, including CNC machine tools, paper, plastic, radar and antenna systems, textile manufacturing, packaging, and military applications.

Features & Benefits

- 20-60 in-Lb Continuous Stall Torque

- Lightweight compact package

- Precision low speed operation,

- High torque-to-inertia, torque to weight ration

- Rugged industrial construction

- Constant pressure brush mechanisms improve brush and commutator life

- Available with integrated brush holder for IP645 rating

- Large, shielded or sealed ball bearings are pre-lubricated

Options

- Premium performance tachometers (3% avg-to-peak ripple)

- Tachometer sensitivities from 1- 30V DC/1000 RPM

- Optical Encoders

- Resolvers

- Custom shaft, Cables and Connectorsconfiguration

- Fail safe Brakes( Spring loaded)

- Gearboxes

- Metric mounting dimensions

- IP65 Sealing

Specification

Specification

Performance

M4000 OVERKILL SERIES

DC Servomotors

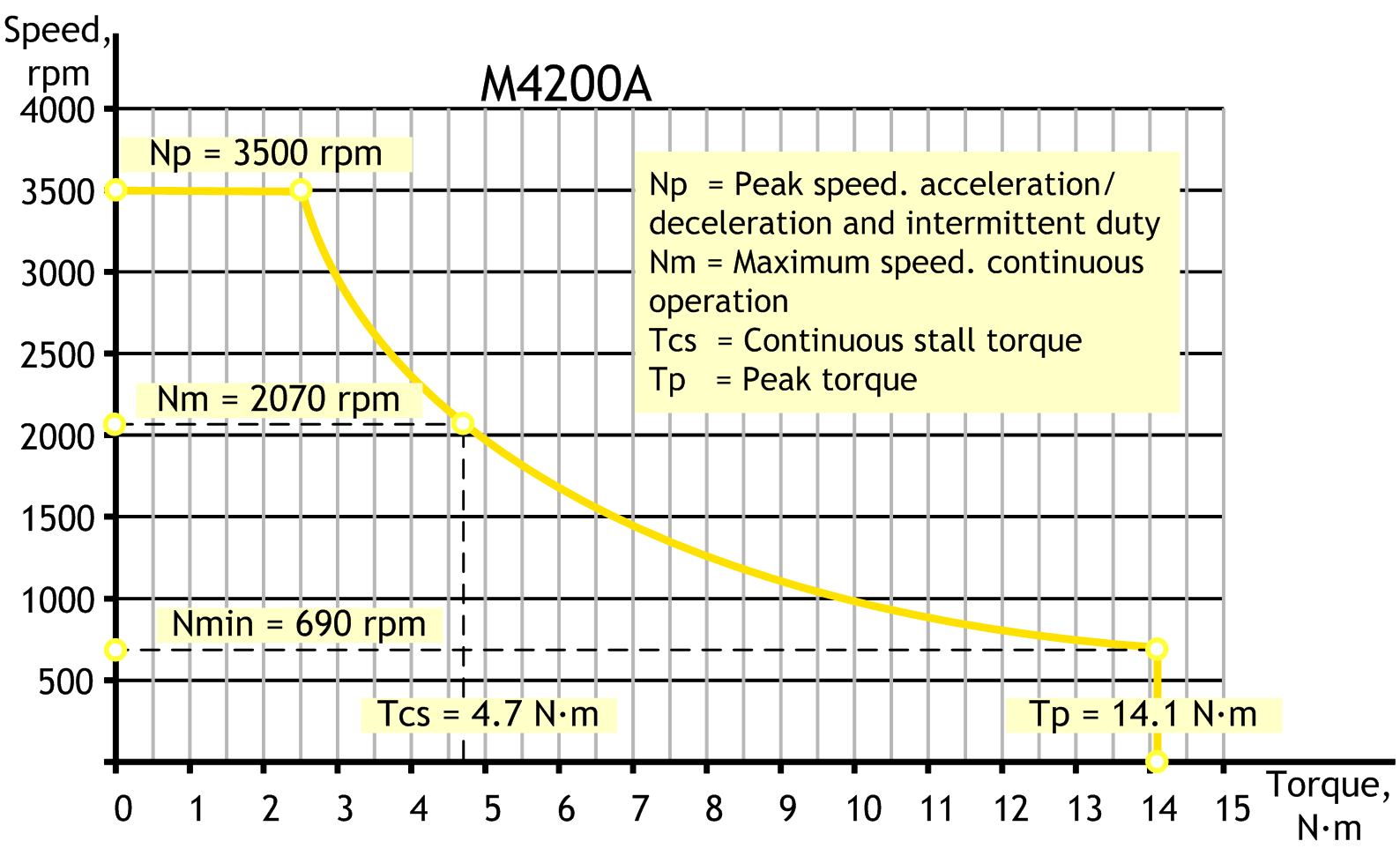

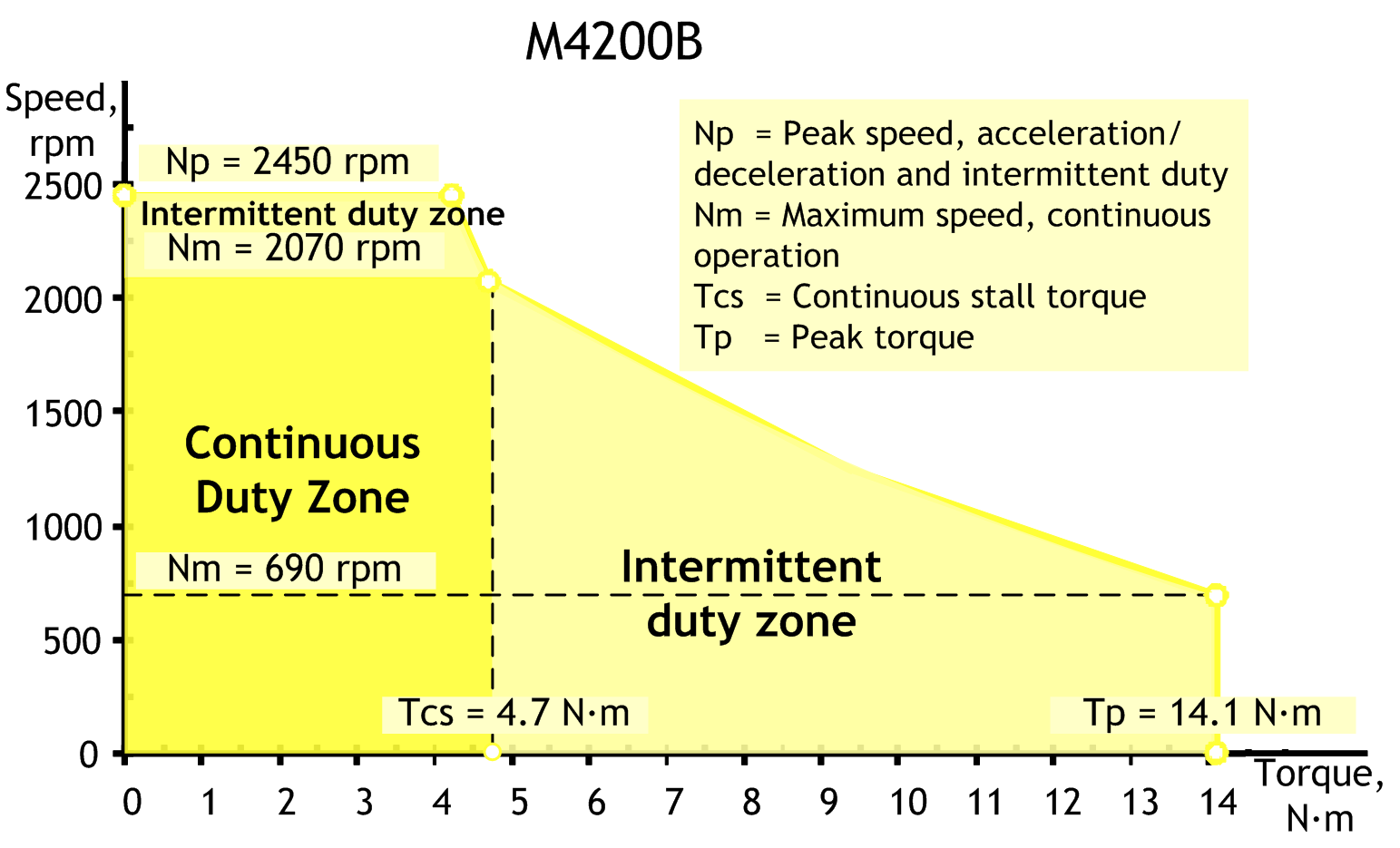

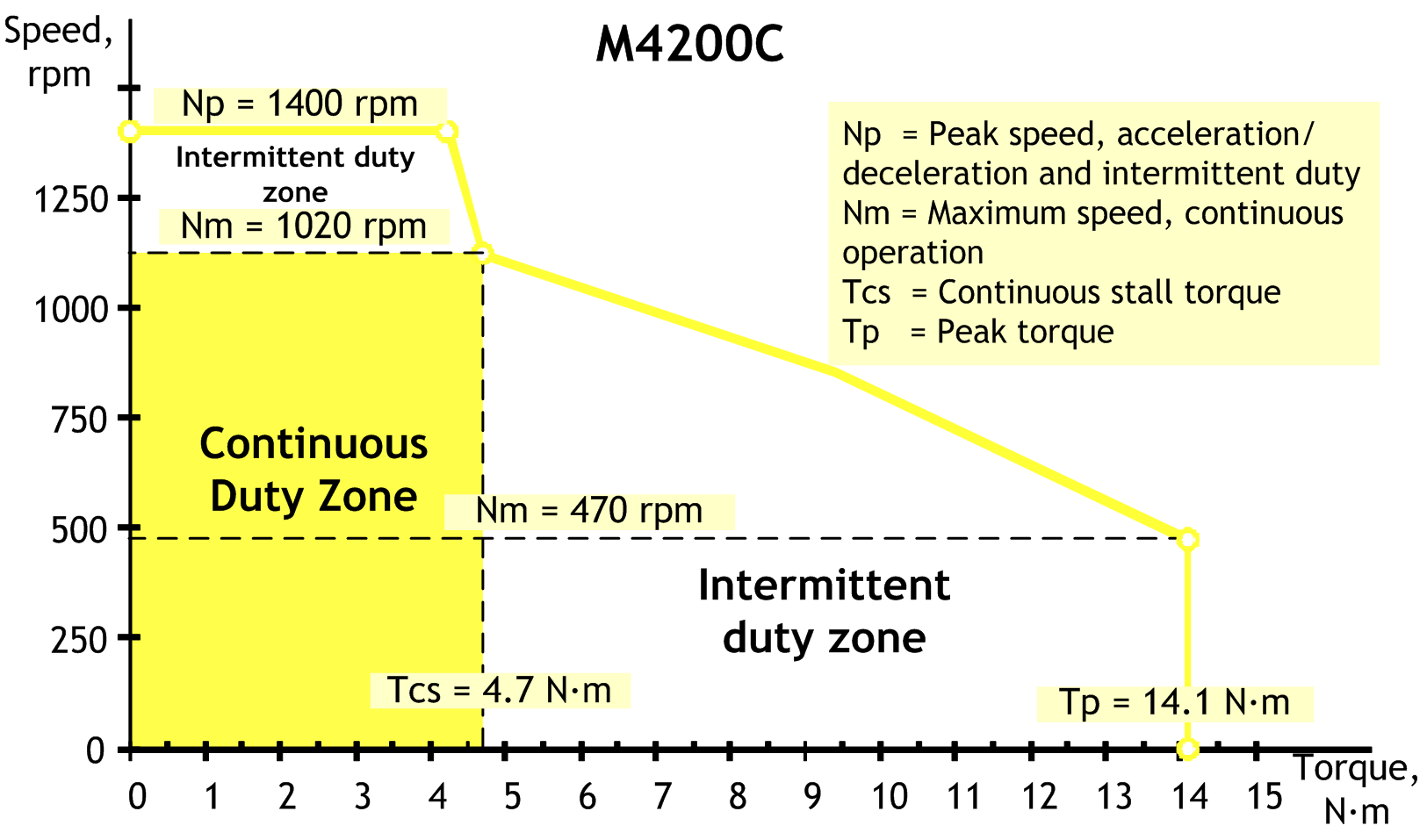

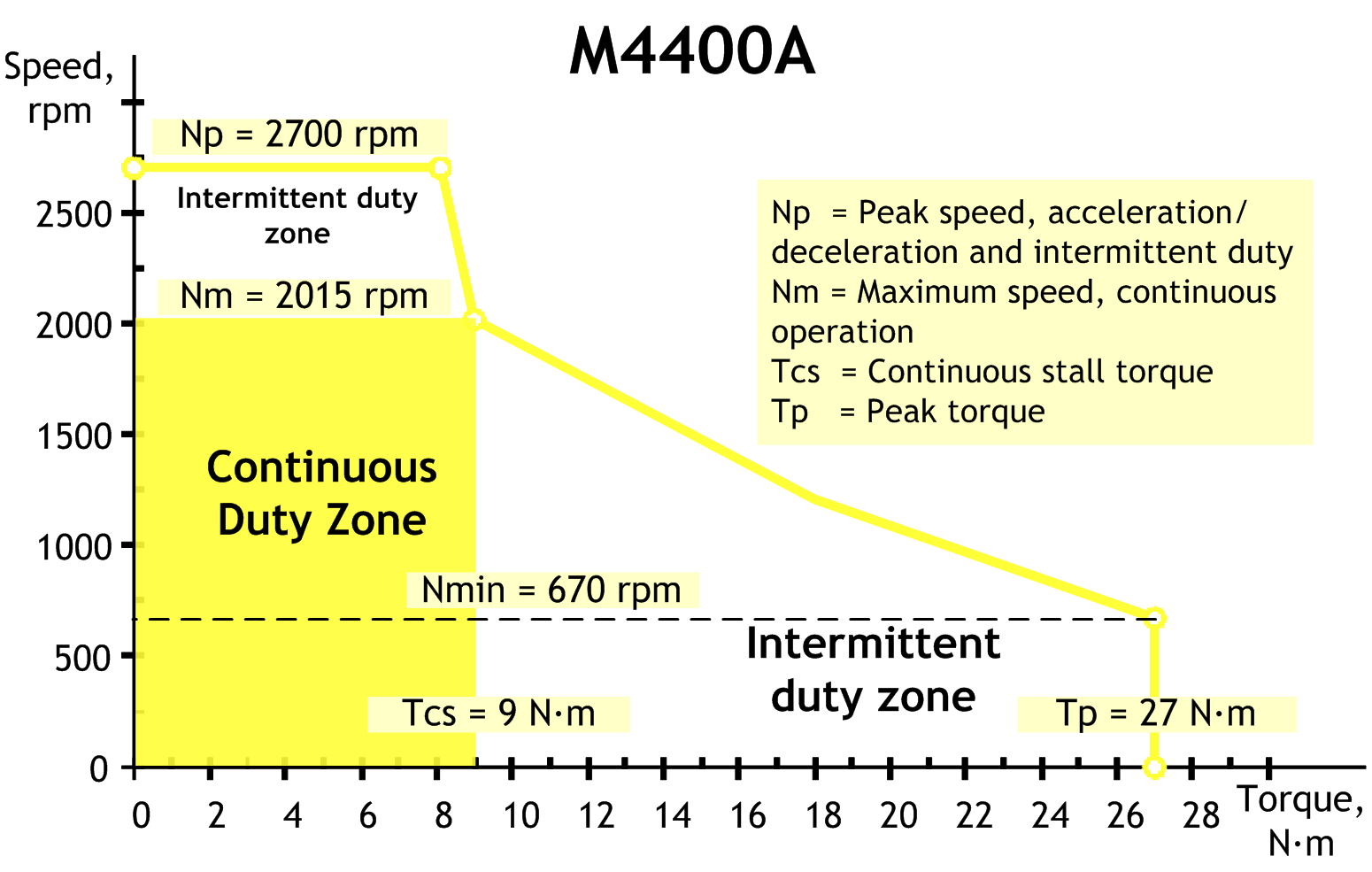

| Motor Parameters | Symbols Units | M4100 | M4200 | M4300 | M4400 | |||||||||||

| A | B | A | B | C | D | A | B | C | D | A | B | C | D | |||

| Horsepower | HP Rated | HP | 1.21 | 0.80 | 1.37 | 1.37 | 0.94 | 1.50 | 1.74 | 1.74 | 1.21 | 2.01 | 2.55 | 2.01 | 1.61 | 2.55 |

| Kilowatts | KW Rated | KW | 0.9 | 0.6 | 1.02 | 1.02 | 0.7 | 1.12 | 1.3 | 1.3 | 0.9 | 1.5 | 1.9 | 1.5 | 1.2 | 1.9 |

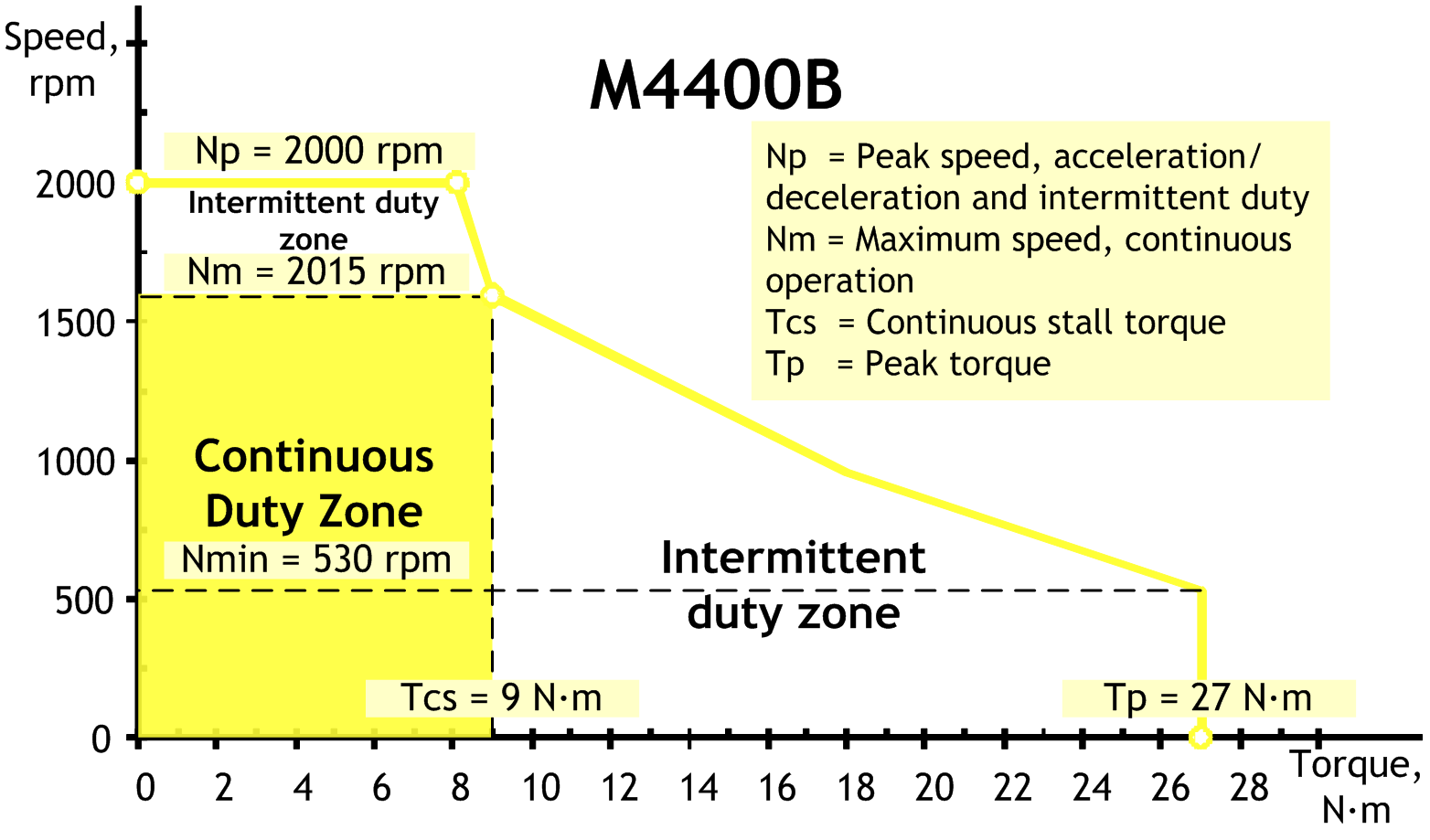

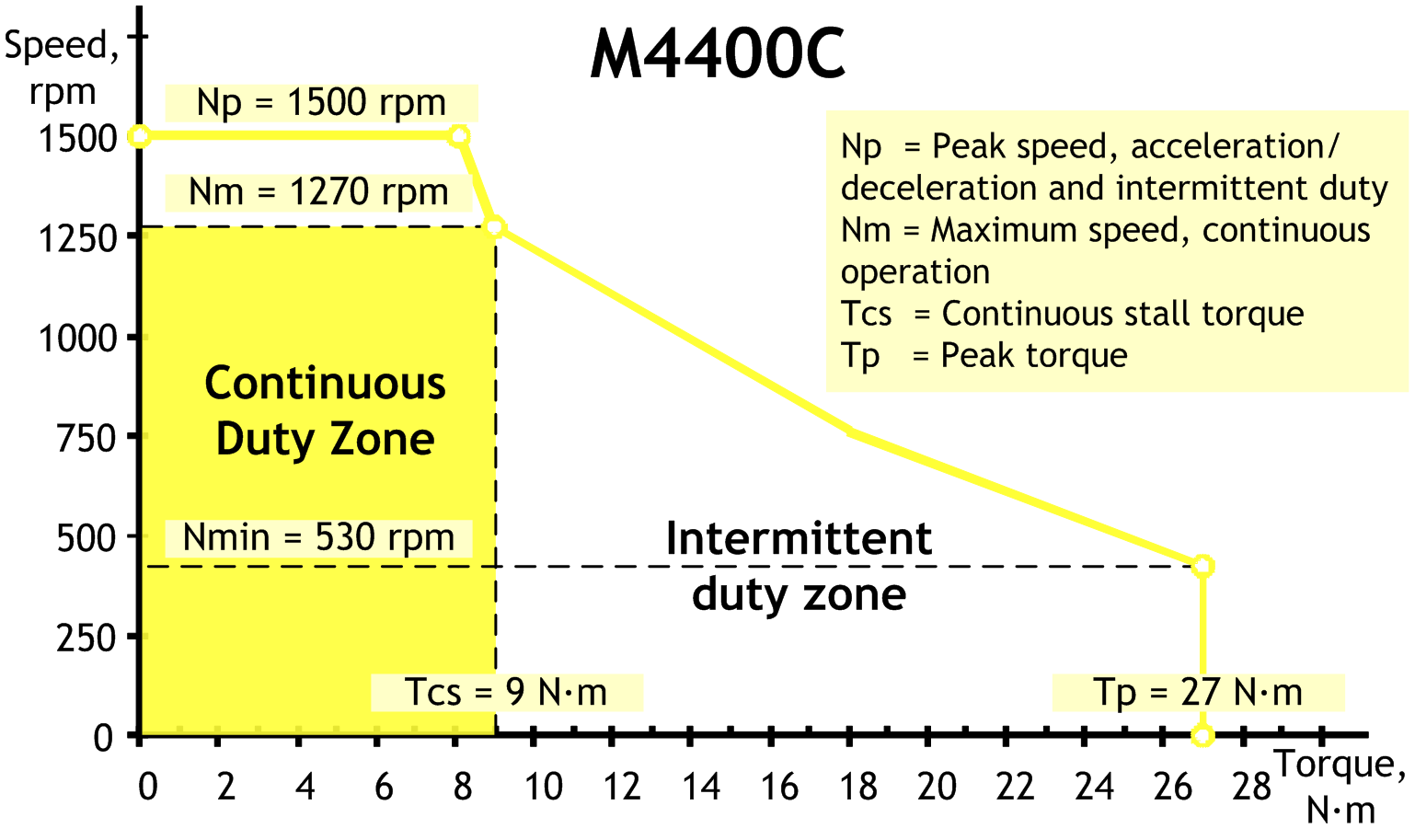

| Max Operating Speed | N Max | RPM | 4500 | 2900 | 3500 | 2450 | 1400 | 4500 | 3000 | 2400 | 1500 | 4000 | 2700 | 2000 | 1500 | 3200 |

| Cont. Torque (stall) | TC | lb-ft | 1.84 | 1.84 | 3.46 | 3.46 | 3.46 | 3.46 | 5.09 | 5.09 | 5.09 | 5.09 | 6.63 | 6.63 | 6.63 | 6.63 |

| @ 40°C amb | N-m | 2.5 | 2.5 | 4.7 | 4.7 | 4.7 | 4.7 | 6.9 | 6.9 | 6.9 | 6.9 | 9 | 9 | 9 | 9 | |

| Current @ cont. torque | IC | amps | 10 | 6.3 | 15.5 | 10.7 | 6.1 | 19.8 | 19 | 14.9 | 9.6 | 26.5 | 21.7 | 16.3 | 13 | 26.1 |

| Peak Torque | TP | lb-ft | 5.53 | 5.53 | 10.39 | 10.39 | 10.39 | 10.39 | 15.26 | 15.26 | 15.26 | 15.26 | 19.90 | 19.90 | 19.90 | 19.90 |

| N-m | 7.5 | 7.5 | 14.1 | 14.1 | 14.1 | 14.1 | 20.7 | 20.7 | 20.7 | 20.7 | 27 | 27 | 27 | 27 | ||

| Current @ Peak torque | IP | amps | 30 | 18.9 | 46.5 | 32.1 | 18.3 | 59.4 | 57 | 44.7 | 28.8 | 79.5 | 65.1 | 48.9 | 39 | 78.3 |

| Max Terminal Voltage | Vmax | Volts | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 |

| Torque Sensitivity ± 10% | KT | lb-ft/amp | 0.18 | 0.27 | 0.22 | 0.32 | 0.55 | 0.18 | 0.29 | 0.35 | 0.59 | 0.44 | 0.31 | 0.41 | 0.52 | 0.26 |

| N-m/amp | 0.25 | 0.37 | 0.3 | 0.44 | 0.74 | 0.25 | 0.4 | 0.48 | 0.8 | 0.6 | 0.42 | 0.55 | 0.7 | 0.35 | ||

| Back EMF Constant | Kv | V/K RPM | 26.13 | 38.67 | 31.35 | 45.98 | 77.33 | 26.13 | 41.80 | 50.16 | 83.60 | 62.70 | 43.89 | 57.48 | 73.15 | 36.58 |

| DC Resistance ± 12% | RT | ohms | 0.69 | 1.65 | 0.37 | 0.71 | 2.31 | 0.23 | 0.26 | 0.44 | 1.25 | 0.158 | 0.26 | 0.43 | 0.69 | 0.19 |

| Inductance ± 30 % | LM | MH | 1.8 | 4.5 | 1.6 | 2.6 | 9.4 | 0.8 | 2 | 1.2 | 8 | 1 | 1.2 | 2.2 | 3.2 | 0.8 |

| Rotor Inertia | JM | lb-ft-sec2 | 0.0007 | 7E-04 | 0.001 | 0.001 | 0.001 | 0.001 | 0.0015 | 0.0015 | 0.0015 | 0.0015 | 0.002 | 0.002 | 0.002 | 0.002 |

| Kg-m2 | 0.0009 | 9E-04 | 0.00135 | 0.00135 | 0.0014 | 0.001 | 0.002 | 0.002 | 0.002 | 0.002 | 0.0027 | 0.003 | 0.0027 | 0.0027 | ||

| Weight | WT | lb | 14.3 | 14.3 | 17.4 | 17.4 | 17.4 | 17.4 | 22.6 | 22.6 | 22.6 | 22.6 | 28 | 28 | 28 | 28 |

| Kg | 6.49 | 6.49 | 7.89 | 7.89 | 7.89 | 7.89 | 10.25 | 10.25 | 10.25 | 10.25 | 12.70 | 12.70 | 12.70 | 12.70 | ||

| Tachometer Parameter 3% ripple pp at 1000 RPM. 2.6k Min load resistance | ||||||||||||||||

| Voltage Sensitivity ± 10% | KG | RPM | 3,7,15,19V avaialble | 3,7,15,19V avaialble | 3,7,15,19V avaialble | 3,7,15,19V avaialble | ||||||||||

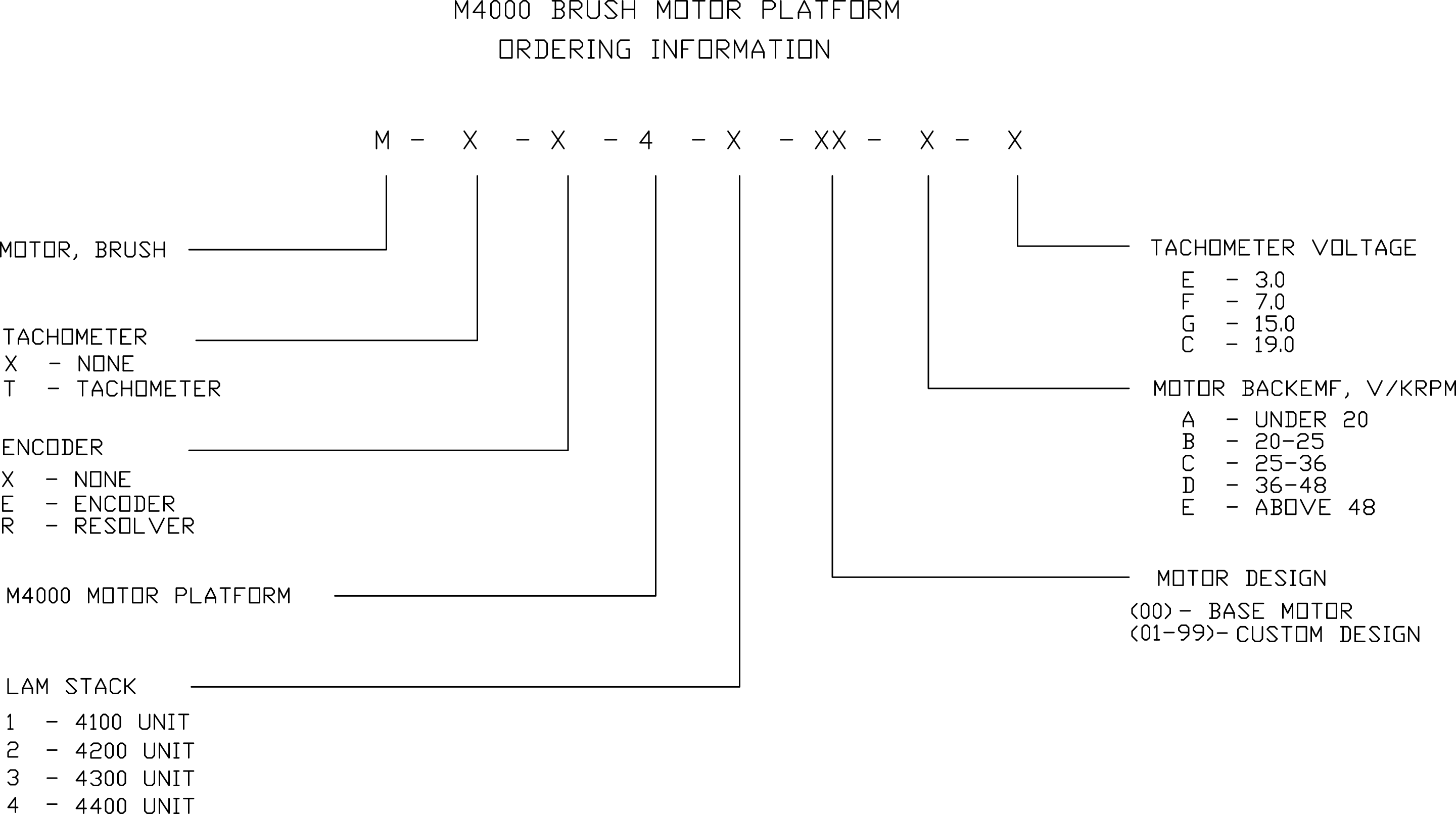

Model Number

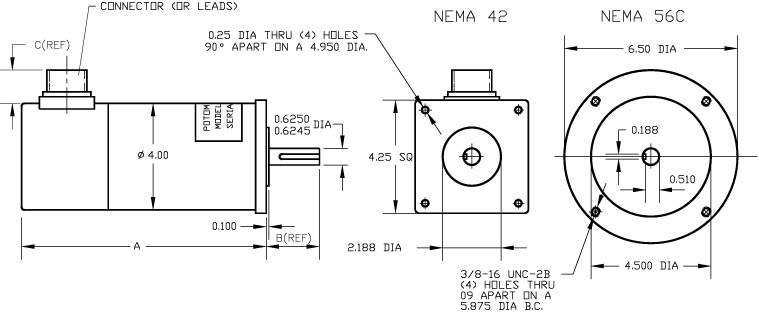

Dimensions

| Description of servomotor | Type | |||

| 4100 | 4200 | 4300 | 4400 | |

| Servomotor | 5.90 | 6.90 | 7.90 | 9.50 |

| Servomotor with tachometer | 6.80 | 7.75 | 8.90 | 10.50 |

| Servomotor with encoder | 6.80 | 7.75 | 8.90 | 10.50 |

| Servomotor with tachometer & encoder | 8.25 | 9.18 | 10.30 | 12.00 |

Documents

Documents

M8000 High-performance DC Brush Servo Motors

High-Performance DC Motor for Precision Variable Speed and Servo Applications

The M8000 is a high-performance DC servo motor designed for variable speed and servo applications. Originally developed for use in hydraulic pumps and traction systems requiring high torque and power, the M8000 offers a compact design with high power density and exceptional starting and continuous torque. Featuring high-energy permanent magnets, the M8000 is lighter and more efficient than traditional series/shunt wound motors. Known for its simplicity and reliability, the M8000 is commonly used with DC power supplies. Additionally, the motor can easily be converted into a high-performance servomotor by integrating a feedback device for precision control.

Features & Benefits

- Open, TENV and TEFC enclosures are available

- UL and CSA listing attainable

- Constant pressure brush mechanisms improve brush and commutator life

- Large shielded or sealed ball bearings are pre-lubricated

- C-face is standard on all models, while optional bolt-on bases provide additional mounting options

Options

- Feedback devices such and encoders and resolvers for precision servo applications

- Shaft length and diameter

- Metric mounting dimensions

- Custom mounting brackets

- Various current and voltage ratings

- Resolver and Encoder feedback for servo applications

- Tachometer feedback 7- 30V DC/1000 RPM

Specification

- Voltage Range: 12-72 volts (battery powered applications) 90 and 180 volts (rectified power supplies)

- Ratings: 2 through 15hp ( up to 5500 RPM depending on speed and voltage)

- Current rating: Up to 700A peak

- Insulation: Class For Class H

Performance

Performance

Model Number

Model Number

Dimensions

Dimensions

Documents

Documents